Note 2 : The enable (EN) input signals specified in the IEC 61131-3 programming standard make retentive off-delay timers possible (by de-activating the enable input while maintaining the “IN” input in an inactive state), but bear in mind that most PLC implementations of timers do not have separate EN and IN inputs.

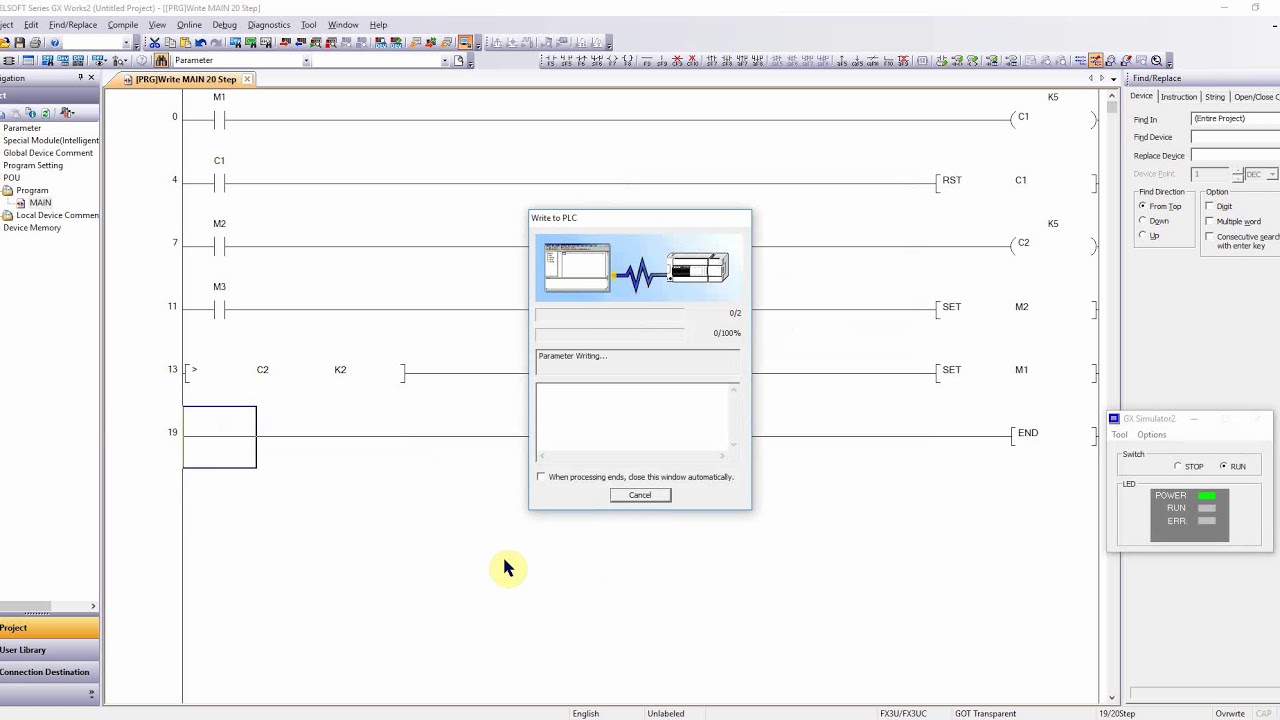

Typically, off-delay timers are non-retentive only (Note 2 ). While it is common to find on-delay PLC instructions offered in both retentive and non-retentive forms within the instruction sets of nearly every PLC manufacturer and model, it is almost unheard of to find retentive off-delay timer instructions. If we wished to give the operator the ability to manually reset the total run time value to zero, we could hard-wire an additional switch to the PLC’s discrete input card and add “reset” contacts to the program like this: The ENO output signal serves no useful purpose in this particular program, but it is available if there were any need for other rungs of the program to be “aware” of the run-time timer’s status. Note 1 : The “enable out” (ENO) signal on the timer instruction serves to indicate the instruction’s status: it activates when the enable input (EN) activates and de-activates when either the enable input de-activates or the instruction generates an error condition (as determined by the PLC manufacturer’s internal programming). This allows the motor to be started and stopped, with the timer maintaining a tally of total motor run time. However, when that bit de-activates (becomes “false”), the timer instruction as a whole is disabled, causing it to “freeze” and retain its current time (CT) value ( Note 1 ). When the motor’s contactor bit (OUT contactor) is active, the timer is enabled and allowed to time.

This “freezing” of operation has the effect of retaining the current time (CT) value even if the input signal de-activates. The general concept of the enable (EN) input is that the instruction behaves “normally” so long as the enable input is active (in this case, non-retentive timing action is considered “normal” according to the IEC 61131-3 standard), but the instruction “freezes” all execution whenever the enable input de-activates. The IEC 61131-3 programming standard, however, addresses the issue of retentive versus non-retentive timers a bit differently.Īccording to the IEC 61131-3 standard, a timer instruction may be specified with an additional enable input (EN) that causes the timer instruction to behave non-retentively when activated, and retentively when de-activated. Most PLCs provide retentive and non-retentive versions of on-delay timer instructions, such that the programmer may choose the proper form of on-delay timer for any particular application. This makes it useful for keeping “running total” times for some event. This ensures the timer resets itself when the operator releases the “Start” push-button.Ī retentive ondelay timer, by contrast, maintains its elapsed time value even when the input is de-activated. Instead, the elapsed time value should reset back to zero every time the input de-activates. This means the timer instruction should not retain its elapsed time value when the input is de-activated. An important detail regarding this particular timer’s operation is that it be non-retentive.

0 kommentar(er)

0 kommentar(er)